| DuraBelt Quick Connect Twisted belts are also called connectable belts, twisted O-rings, quick-fix belts, zero downtime bands, and easy hook round belts. Twisted belting is designed to replace urethane endless round belts that become damaged or wear out. These connectable belts are easily and quickly installed in the field without dismantling drive shafts. The tips of quick fix belts are loops that you connect together with small stainless steel or plastic hooks that come with the belts. |

All sizes, materials, colors and hooks

Twisted Belts

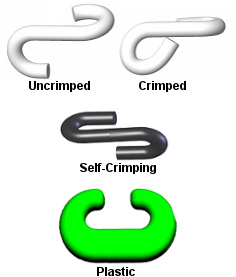

Three Types of Hooks

Round Connectable Belt

Connect by hand, or

Connect with

Speedy Belt Installer

|

- Eliminate costly downtime.

- No need to drop shafts.

- Installs in seconds with Speedy Belt Installer (SBI)

- No need to drop rollers with SBI.

- Lengths from 2" to 300 ft. (50mm to 100 meters).

- Measure them from tip to tip, excluding hook.

- Cross sections: 3/32", 1/8", 5/32", 3/16", 7/32", 1/4", 5/16", 3/8", 7/16", 1/2", 9/16", 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 9.5mm, 11mm, 12mm, 14mm. (These are the effective diameters that two strands of twisted cord produce. For example, this means our Twisted 3/16" belt replaces a 3/16" round o-ring belt.)

- Available in many colors.

- Durometers 80A to 95A.

- Available in Anti-Static (static dissipative)

|

Critical: Because they are coiled like springs, twisted belts stretch more than round belts. Most round belts are stretched approximately 10%, while twisted belts are typically stretched 17%, so twisted belts should be about 7% shorter than the o-ring belts they replace.

NEW:

Patented self-crimping stainless steel hook

tightly wedges belt loop into hook so no crimping is required. Achieves maximum belt life by eliminating friction between hook and belt loop that ultimately cuts through the loop. Only available on 3/16" twisted belts (i.e., made with two strands of 1/8" cord). Disadvantage -- difficult to install and nearly impossible to unhook if the belt is installed backwards, so the belt must be cut off and thrown away.

When ordering, specify easy-to-install stainless steel, self-crimping stainless steel, or long lasting plastic hooks.

Connectible Round 3/8" (9.5mm) Belts, are used where a twisted belt is too bumpy. When used with large plastic hooks, they are ideal for applications in the glass or film industry, where a broken steel hook might scratch materials or tooling. The 100A durometer loops (red) will not pull out or stretch. Available in any length. The maximum recommended stretch for 83A orange cord with large plastic hooks is 6%.

NEW Abuse Resistant Rough Green Twisted Belts are harder and have a lower coefficient of friction that lets them slip easier when boxes jam, so there is less heat build up. This means they can take more abuse. Made from 88A cord, their higher tension helps offset their tendency to slip, so they provide almost as much drive as 83A belts. Works exceptionally well on high speed lineshaft curves where belts rub hard and fast against roller grooves. Stretch them 14%. Use only with plastic hooks.

|

|

We recommend the Speedy Belt Installer because it greatly reduces the installation time of twisted belts down to about 25 seconds. Click on the picture below to learn more about it.

|

How to measure Twisted Belts

|

How to specify Twisted belt's thickness:

- Best way: Measure and tell us the thickness of the round, endless belt that the twisted belt will replace.

- Next best way: Measure and tell us the thickness of the single strand at the end of the loop of an UNUSED twisted belt. (Used belts have stretched and become thinner.) After we fuse and stretch two strands, the belt will be thinner than twice that measurement, but thicker than the single strand.

- Least best way: Measure and tell us the crest-to-crest thickness of an UNUSED twisted belt. It will always measure slightly thicker than the endless belts it replaces, as in the chart below.

- If still in doubt, ask for a free sample to confirm the thickness before buying large quantities.

Twisted Belt Thickness Chart

|

|

Twisted belts are adjustable: You can shorten and tighten Twisted Belts or make the belt loops smaller by simply twisting one end (while holding the other end) before hooking the belt together. One complete revolution shortens the belt by about 1/10 inch. Therefore, if you twist it 5 times before hooking the ends, the belt will be 1/2" shorter and provide greater tension.

Lifespan: Twisted belts were originally designed as temporary replacements for round belts. The intent was to keep the conveyor running until the next vacation when the preventive maintenance department would tear down the conveyors and replace all round belts whose lifespan had been exceeded. However, twisted belts are so fast and easy to replace that many are used in place of round belts with the expectation that they will break at the loop and be replaced more frequently.

It is easy to see why that cannot last as long as round belts. Two strands of twisted cord contain about 89% as much urethane as one strand of the round belt that they replace, so they will only last 89% as long, at best. They usually fail when the hook pulls through the loop, which is only half as thick as the rest of the belt. Consequently, twisted belts with uncrimped metal hooks typically last about 30% to 60% as long as endless round belts. Belts with crimped metal hooks or self lubricating plastic hooks typically last somewhat longer. More info.

For the best in twisted belts, false twist drive bands, connectable belts, twisted O-rings, zero downtime belts, and easy hook round belts, insist on DuraBelt twisted belting. |

Copyright © 2025 Dura-Belt, Inc. All Rights Reserved. Site Index

|