| Dura-Belt | 800-770-2358 | WHERE TO BUY | ||

| Next Product |

V-Conform™ Reinforced O-ring Belts

(aka Ultra-Drive™ belts)

This belt is designed to compete with Fenner's Eagle® XLD O-ring. We believe our V-Conform belt (aka Ultra-Drive Belt) is much better because it delivers the claims that XLD O-ring fails to provide. See Eagle XLD O-ring Review.

V-Conform Reinforced O-ring Belts

(aka Ultra-Drive Belts)

Finger Guards Required*

DC Amps Compared

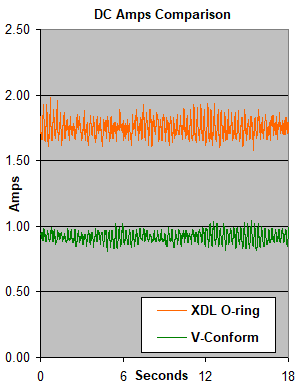

After 3 days of continuous running 24/7 at low speed (115 ft/min) on a ten roller zone powered by an MDR with a PLC that has a maximum continuous current rating at highest speed of 2.8 amps

Rollers vs MDR Current

New V-Conform Reinforced O-ring belts

are Bi-Modulus (rubber reinforced with elastic "stretchy" nylon) so they provide greater tension than solid polyurethane belts, letting you move heavier boxes, faster and with longer zones.Conforms to grooves:

V-Conform belts have soft tiny ribs that conform to standard 3/16" roller grooves so they can replace round elastic belts, while providing nearly as much grip and tension as two rib (2PJ) poly-v belts.Ultra High Tension = Finger Guards:

Like poly-v belts, XLD O-rings and chains, V-Conform belt's tension is so high that they create pinch points that require finger guards (safety guards) where personnel work within reach of boxes on conveyors. Regardless of what Fenner claims, they are "drop in replacements" ONLY where humans can NOT come in contact with them. We can provide single unit multi-finger-guards with up to 9 fingers (adjacent picture shows 5 fingers). They are made from aluminum and require machined or laser-cut slits in the frame for each finger, plus at least two holes.No-Stretch belts stress MDRs:

Idler (slave) rollers are not precision rollers because they can be slightly bowed, elliptical (un-round) and/or have shafts slightly off center, so they act like small cams that wobble slightly with every revolution. No-stretch belts, like Eagle XLD O-rings, transmit that wobble directly to MDR motors, creating current spikes that hammer, overheat and stress MDRs, as shown by the orange, high current spikes on the adjacent graph. This causes XLD O-rings to waste energy and reduce MDR lifespan**.V-Conform belts protect MDRs:

Like solid polyurethane belts, V-Conform belts stretch (up to 7%) and relax to absorb cam shocks, so they reduce current surges and help protect MDRs, as shown by the green, milder current spikes on the adjacent graph.V-Conform belts save Energy and MDRs:

Compared to XLD O-rings, V-conform belts cut energy consumption nearly in half and help prevent MDRs from overheating. When an MDR overheats for more than a few minutes, thermistors shut it down until it cools. Unfortunately, thermistors only work for a limited number of times, e.g. 30 incidents. When that limit is reached, they burn out. If the one inside the MDR burns out, the MDR is usually not repairable.Prevent bearing and shaft hole wear:

V-conform stretchy belts help prevent bearing and shaft hole wear caused by no-stretch belts and wobbly rollers that hammer bearings and shaft holes.Wipe away dust, prevent slipping:

V-Conform belt's tiny ribs open and close with each rotation, wiping dust out of roller grooves. Helps prevent slipping.Easier to Install:

Center distances between rollers have tolerances on the plus-side that make no-stretch belts extremely difficult to install when frame holes are slightly wider apart, but still within tolerance. Stretchy V-Conform belts overcome that problem, regardless of tolerance range. They stretch and conform.Powers longer zones:

Since V-Conform belts use less energy, they can power up to 30 rollers without exceeding the high speed current rating. See green line in adjacent graph.Anti-static:

Unlike XLD belts, V-Conform belts are anti-static.Test results to date

: During the last 21 months for a total of 24,090 operating hours, conveyor manufacturers and Dura-Belt have been testing V-Conform belts. The belts at Dura-Belt have been running 24/7 at high speed (200 ft/min), equivalent to 7 years of 40 hour weeks. Last month we noticed that some of the belts began to slip slightly when we held static the 5th slave roller in the zone. This caused the MDR to slow down but not stop. Also one of the belts had one of its several reinforcing cords stick out from the side of a belt. Thus it appears the belts are near the end of their lifespan.Theoredically, if the high speed is reduced by half to 100 ft/min, then the belt's flex life should be doubled to 42 months, which is equivalent to a lifespan of 14 years of 40 hour weeks. Moreover, since most conveyor manufacturers assume MDR zones are only running half the time, this would increase lifespan to 84 months and 28 years of 40 hour weeks. Note, however, that these tests were performed without any load or jams. Therefore, lifespan would likely be reduced by the weight of the containers and number of jams, but we have no way to measure this.

V-Conform belts are highly slip resistant. When we grab the end roller, stopping its rotation, none of our V-Conform belts slip and the MDR stalls (stops rotating). This V-Conform video shows that V-Conform belts do NOT slip. Compare it to this XLD O-ring video. It shows that XLD O-rings slip like when boxes jam or accumulate. Such slipping means that XLD O-rings can overheat, abrade and fail prematurely just like traditional O-ring belts. Non-stretch XLD O-rings provide excessive tension that can damage MDRs and bearings, but their slipping means that they have a much lower coefficient of friction than V-Conform belts. This means that XLD O-rings should not be able to transfer nearly as much power as claimed, while V-Conform belts will transfer such power easily without slipping so they are much more efficient.

Incidentally, all our MDRs driving V-conform belts are running warm to the touch, not overheated like MDRs driving XLD O-rings.

Curve Test:

We tested V-conform belts on conveyor curves and skews. They should NOT be used on curves because rubbing against groove sides causes the belts to abrade. However, they work well on skews, but only where belts impinge on rollers at 90° angle (i.e., are perpendicular to rollers). In our tests, XLD O-rings also ultimately abraded on curves, plus energy consumption greatly increased.**MDR lifespan and cost:

Unfortunately, there are no free lunches. Most MDRs and pancake motors are warranted for "normal and proper use". No-stretch Eagle XLD O-rings powering wobbly idler (slave) rollers can hammer and overheat MDRs so they should not be categorized as "normal use". This means XLD O-rings may reduce MDR lifespan and require replacement more often. Since MDRs cost more than expensive no-stretch XLD O-ring belts, Eagle XLD O-rings may not save money in the long run and cost considerably more than V-Conform belts or polyurethane round belts.V-Conform Advantages:

- Moves heavier boxes, faster and on longer roller zones than XLD O-rings and polyurethane o-ring belts (PU belts).

- Replace 2 rib poly-v belts without needing poly-v endcaps by installing them in standard round grooves on inexpensive, non-precision idler rollers - thereby significantly reducing total costs.

- "Drop in replacements" for PU belts in areas where employees are restricted from proximity to conveyors, or where V-Conform belts are located out of reach, like deep inside diverters.

- Potential longer life that PU belts, thereby reducing maintenance costs. Time will tell.

- If allowed to rest (not run continuously), like 2 seconds on and 1 second off, they can move heavier boxes (perhaps up to 320 lbs) at higher speeds while protecting MDRs from overheating and shut downs. This helps moderate electricity costs and protect MDR lifespan.

- Greatly increases drive force in critical applications like merges and squaring boxes for robots that stack them on pallets.

- Due to minimal belt creep, there is virtually no noticeable reduction in box speed at zone end.

- Works over wider temperature range than PU belts, -22°F to 176°F (-30°C to 80°C).

- Like Poly-V belts, thin V-Conform belts can theoretically run at very high speeds, up to 800ft/min (4M/sec), but roller precision might be a limiting factor so you should test the belts at high speeds before buying a large quantity.

- Our low cost molds are available to make different lengths in 6 weeks so special lengths are no problem.

- Higher coefficient of friction resists slipping better than XLD O-rings and PU belts.

- According to our high speed (200 ft/min) test continuously running 24/7 with light load, belt lifespan is approximately 24,000 hours or 7 years of 40 hour weeks.

V-Conform Disadvantages:

- Costs more than PU belts.

- Increases electricity costs by 30%.

- We have not tested this yet, but it will probably use more energy than poly-v belts.

- When moving 25 or more rollers continuously at high speed, it may require a larger power supply.

- Requires extra long 4.5" (114mm) finger guards where employees have unrestrained access to conveyors.

- Increases labor costs slightly (screwing two screws in or out) to install and remove finger guards where they are required. Finger guards must be installed after installation of V-Conform belts and removed before replacing V-conform belts.

- Requires additional slits and holes in conveyor frames to mount finger guards, plus a self-threading screw.

- Will abrade and not work long on curves.

- Not green: Neither biodegradable nor recyclable like PU belts.

Eagle® is a registered trade mark of Fenner Drives.

V-Conform™ is a trade mark of Dura-Belt, Inc., March-20-2023.

Special thanks for excellent technical help, priceless knowledge and conveyor parts furnished by QCON-24

For the best in V-Conform Reinforced O-ring belts and Reinforced belts, insist on Dura-Belt.

| Next Product |

Copyright © 2025 Dura-Belt, Inc. All Rights Reserved. Site Index