| Dura-Belt | 800-770-2358 | WHERE TO BUY | ||

Eagle® XLD O-rings Review

--------------- November 2023 update to our July 2023 review below ---------------

Fenner also added a warning in hard-to-read cigarette-style italic print that their XLD O-rings "can create pinch points, which should be properly safeguarded to prevent injury". Nevertheless, in the main text they still falsely claim that XLD O-rings are “a simple, drop-in replacement” for traditional O-ring belts. Fenner is still trying to have it both ways.

Recently, our new tests cast doubt on Fenner's remaining claims that Eagle XLD O-rings provide "Xtra Life, Xtra Load, and Xtra Savings".

This XLD O-ring test video shows that after 3 months of continuous (24/7) running, Eagle XLD O-rings SLIP when a roller is held by hand -- like when boxes jam or accumulate. This means they can overheat, abrade and fail prematurely.

Since lower cost, traditional O-ring belts also slip under the same test, it is difficult to believe that expensive XLD O-rings will "last at least 6 times longer", move boxes weighing 320 lbs, power 30 rollers with one MDR, and provide extra savings. Therefore, we think Fenner also needs to remove their dubious claims.

Incidentally, we have been running our competing V-Conform belt in the same test for 16 months. This

V-Conform belt test video shows that V-Conform belts do NOT SLIP. Non-stretch XLD O-rings provide ultra high tension that can damage MDRs and bearings, but their slipping means that they have a lower coefficient of friction than V-conform belts. We will continue our V-Conform belt tests until they start to slip, but now, they are looking like ULTRA DRIVE Belts that will greatly outperform Eagle XLD O-rings.

----------------------------------------- July 2023 Review ----------------------------------------

Eagle XLD O-rings Comparison

| Meter reading | XLD O-rings Belt (reinforced with Kevlar) | V-Conform Belt (reinforced with stretchy nylon) | HT Blue belt (unreinforced polyurethane) | Number of Rollers in Zone |

| LOWEST Speed (ft/min) | 115 | 115 | 115 | 10 |

| Peak DC Amps* | 4.33 | 2.33 | 1.55 | 10 |

| Average DC Amps* | 1.75 | 0.91 | 0.61 | 10 |

| MDR temperature (hand gripped the motor area) | Hot | Warm | Warm | 10 |

| ---------- | ---------- | ---------- | ---------- | ---------- |

| HIGHEST Speed (ft/min) | 179 | 201 | 201 | 10 |

| Peak DC Amps* | 5.45 | 3.78 | 2.30 | 10 |

| Average DC Amps* | 2.10 | 1.36 | 0.93 | 10 |

| MDR temperature (hand gripped the motor area) | Too Hot to hold | Hot | Warm | 10 |

| ---------- | ---------- | ---------- | ---------- | ---------- |

| HIGHEST Speed (ft/min) | 158** | 186** | 201 | 15 |

| Peak DC Amps* | 7.26 | 4.07 | 2.85 | 15 |

| Average DC Amps* | 3.56 | 1.83 | 1.14 | 15 |

| MDR temperature (hand gripped the motor area) | Overheated shut down after 1 hour | Hot | Warm | 15 |

Reduce energy costs?

False Advertising! For 9 months Fenner's ads claimed their Eagle XLD O-rings reduce energy costs. They recently removed that claim, but they need to broadcast a retraction because our tests show that at low speed their belts used almost twice as much energy as our V-Conform belts and nearly three times as much energy as our HT Blue polyurethane belts. At highest speed, running continuously, Eagle XLD O-rings ran too hot-to-hold, over stressing our MDR without any load on the conveyor! When powering our 15 roller zone at highest speed, running continuously, they overheated and shutdown our MDR, potentially reducing its lifespan.No Stretch Belt?

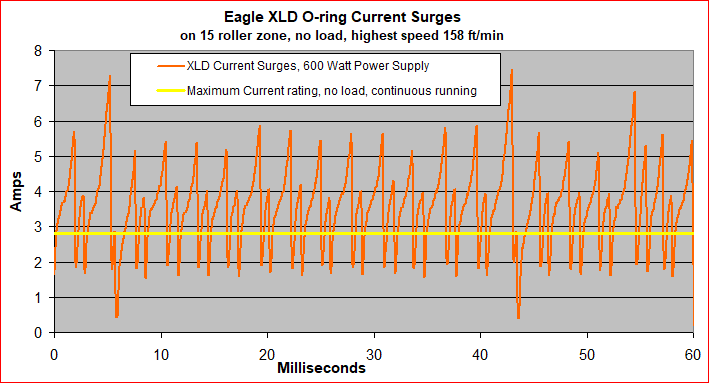

Fenner touts this as an advantage, but they don't seem to understand that idler rollers are not precision rollers. Instead, they often WOBBLE due to being slightly elliptical and/or slightly bowed and/or have shafts slightly off center. Moreover, belt grooves can vary slightly in depth even on the same roller. This off-center wobble means rollers act like small cams forcing no-stretch belts to put significant strain on motors with every roller rotation. Such "cam shock" causes motors to draw excessive current, close to the maximum current allowed, so they have little room to move heavier loads, faster and on longer zones. Poly-v belts on precision poly-v endcaps do not have such huge "cam-shock" problems because they run on precision grooves on perfectly round endcaps, and they are located on the end of the roller where bowed roller tubes have little effect.

Frayed Eagle XLD O-ring

on 6° curve

Longer belt life?

Fenner's so-called "D" belts are really "T-top half-round" belts. Their little T-top wings conform to fillets on groove edges. They work well on idlers that have wide grooves and wide fillets, but apparently they were not tested on Itoh Denki MDR's narrow groves and narrow fillets (PulseRoller MDR appears similar), where our tests show that parts of their edges are pressed upward and stick slightly above the roller's surface. This can cause light boxes to rotate. Heavy boxes will likely crush and fray any protruding T-tops. Without T-tops gripping the fillets, it seems reasonably to expect Eagle XLD O-rings to slip easier on those MDRs. Will this also reduce XLD's lifespan? On 6° curves, a test by another company shows Eagle XLD O-rings can fray after running only 160 hours.

Eagle XLD O-rings T-top may protrude above MDR's surface

6 times longer life?Polyurethane round belt's lifespan can vary widely, depending upon how they are used or abused. In a real world test in an ideal temperature and humidity controlled environment with precision rollers (TIR 0.015"), nearly all 40,000 HT Blue belts were still running strong after 9 years in a USPS distribution center. A major conveyor manufacturer warrants them for running five years, so without actual real world tests, claiming Eagle XLD O-rings will last up to 6 times longer is a stretch. Perhaps Fenner is comparing XLD to their 3/16" Eagle O-rings that have had recent problems with breaking weld joints. However, the problem for no-stretch belts is not the belt's lifespan, but rather the MDR's lifespan. XLD's no-stretch O-rings hammer MDRs and roller bearings with every rotation. You can see the hammering on an oscilloscope (see high resolution graph at bottom of this page) and feel how much hotter the MDR is. Years ago, such hammering also caused minimal-stretch Gygaprene belts to be discontinued because they adversely affected MDR lifespan. Conversely, 33 years of experience prove that our elastic polyurethane belts easily stretch and absorb "cam shock", thereby protecting motors and bearings. |

Current Surges |

Reduces System Costs?Eagle XLD O-rings cost 3 to 5 times more than the urethane belts they replace. The "cam" effects means they will probably reduce MDR and bearing lifespans so they may have to be replaced more often. Eagle XLD O-rings also operate so close to MDR/PLC maximum current ratings that any kind of jam can cause them to overheat and trigger thermistors that have limited lifespams. When the thermistor inside the MDR dies, it cannot be repaired so that kills the MDR -- an expensive loss. The extra energy needed to drive no-stretch Eagle XLD O-rings boosts the energy needed to increase load, speed or zone length, as is shown by the steeper slope as in the adjacent graph. All these problems greatly limit potential saving, so system costs will likely be significantly higher.Eliminates Some MDRs?The adjacent graph shows that XLD's electric current (amps) usage is so high, even when operating continuously at our MDR's lowest speed (115 ft/min), that the MDR can only move about 14 rollers without exceeding the maximum current rating. When running 15 rollers continuously at high speed, it overheated and shut down our MDR. In other words, Eagle XLD O-rings, running continuously, did not eliminate even one MDR in our test. This also means that they probably do not have much capacity to move heavier boxes at high speeds. |

MDR Current vs Rollers |

Eagle XLD O-rings with Finger Guards

that must be 4.5" (115mm) long

Drop in Replacement for urethane belts?

This is true only in areas where human access is prohibited or not possible (like deep inside a diverter). Finger Guards, like those used on poly-v belts, are required by OSHA in areas where people can inadvertently put a finger under a belt that has a pinch point that can damage fingers. Fenner belatedly added a pinch-point footnote in "hard-to-read" italic type. At the very least they should link the two with asterisks. Otherwise, it looks like they are trying to have it both ways.Easy Installation?

Center distances of holes between rollers have tolerance ranges, typically (+/-.010"). On our test conveyor, the nominal 3" center distances mean rollers are 2.99", 3.00" and 3.010" apart. Using the rollers as levers, installing belts on the first two center distances (2.99" and 3.00") was fairly easy, although it required some effort to tension belts the last 1/16". However, one person could do it. Since Eagle XLD O-rings do not stretch, the 3.010" center distance took two employees to install the belts -- one person had to use both hands to pull the roller in place, while the other person guided the shaft into the hole.Weird Tolerance range:

Eagle XLD O-ring's stated tolerance range (-3%/+0) shows why we needed two employees to install their belts on 3.+010" center distances. Apparently their belt is not designed to run on center distances slightly above nominal, but statistically, on the average, that can happen 1/3 of the time. Does their weird tolerance range mean that slightly over stretching their belts reduces their lifespan?Unfortunately, in areas where finger guards are required, installing the belts on rollers is only half the task. The other half requires installation of extra long 4.5" (115mm) finger guards, which can take much longer, especially if it involves drilling holes in the frame. Once finger guards have been installed, it is virtually impossible to install or remove belts without first removing the finger guards. Conclusion: installation of Eagle XLD O-rings where humans work can be difficult, labor intensive and expensive.

Larger Power Supply Required:

Running with Eagle XLD O-rings at top speed on a 10 roller zone caused our MDR to be too hot to handle. The resulting reduction in top speed (see table above) means our MDR needs a larger power supply that would provide more amps and make it overheat more. On a 15 roller zone running continuously at top speed, Eagle XLD O-rings caused our MDR to thermally shut down. Running 2 seconds on and 1 second off would reduce the average current by 1/3, but the extra energy supplied by a larger power supply, when moving heavier and/or faster loads, would likely raise the average current well over the maximum recommended 2.8 amps, potentially damaging the MDR.Super Sensitive to Roller Alignment:

We noticed that, if the roller grooves are slightly misaligned, the amps and temperature increased significantly and the speed decreased. That means that using Eagle XLD O-rings on skewed rollers, curves and/or longer zones may require still larger power supplies and further reduce MDR lifespan, while possibly overheating and warping plastic covered cartons, products and bags that pause above the hot MDR. Threaded shafts force grooves to be perfectly aligned, but spring loaded shafts usually have gaps between the roller and the frames. When we misaligned the grooves by 1/8" (3mm) on any adjacent rollers, the current jumped 5% to 10% and the speed declined.Not green:

Eagle XLD O-rings and V-Conform belts are not thermoplastic, so they are not recyclable or biodegradable. 97% of our polyurethane belts are recyclable and biodegrade in UV light or warm water.Bi-modulus Technology:

This is a fancy way of saying reinforced, i.e., composed of two different materials. Eagle XLD O-rings appear to be made from thermoset polyurethane reinforced with no-stretch aramid (Kevlar) cord. For years other companies (Volta, Beha, TKF and Fenner) have sold bi-modulus round, vee and/or T-top half-round belts also reinforced with aramid or polyester, so "Bi-Modulus Technology" is nothing new. Incidentally, ConveyXonic Poly-V belts are quadra-modulus, i.e., 4 different materials. Bi-modulus and reinforced T-top half-round belts are prior art, so neither are patentable.*Peak Amps = largest value in the range of 20 data points/second. These are frequently recurring amp spikes, not due to start up surges. *Average Amps = average of 100 data points/0.5 second. The time graph is also plotted using the same average amps.

**MDR: Itoh Denki PM486FS-55-2. Driver card: CB016S7. Power supply: 600 DC watts at 24 volts.

Eagle XLD O-ring Current Surges at High Speed Caused Our MDR to Overheat and Shut Down

Eagle® is a registered trade mark of Fenner Drives.

Special thanks for excellent technical help, priceless knowledge and conveyor parts furnished by QCON-24.

Copyright © 2025 Dura-Belt, Inc. All Rights Reserved. Site Index